LIGHTING OF PRODUCTION ROOMS

MAIN REQUIREMENTS TO LIGHTING INSTALLATIONS OF PRODUCTION ROOMS

Each room of the production building has the certain functional purpose connected with the production technology. And the electric lighting arranged in it has to meet many requirements corresponding to purpose of the room, character of the visual tasks arising at people and some other conditions.

Artificial lighting has to create the certain lighting conditions necessary for the successful solution of visual tasks in rooms. These conditions are characterized by the minimum illumination and requirements to quality of lighting accepted by existing rules of artificial lighting.

Lamps in production rooms settle down so that they provided uniform distribution of illumination on all room or part of the room for which the same illumination is normalized.

In rooms in which at artificial lighting it is necessary to distinguish colors and color shades also correctly as at natural lighting, the choice of types of a light source becomes a decisive factor.

During the whole time of operation of lighting installation illumination shouldn't decrease below a certain level, owing to the fluctuations of tension in a lighting network caused by turning on of powerful power electroreceivers and from rocking or unstable position of lamps.

Lighting installations in production buildings have to be executed so that their convenient and safe operation was provided.

Installations of electric lighting have to conform to requirements of the existing Rules of the device of electroinstallations.

Lighting installations have to possess the greatest economic efficiency whenever possible.

NORMS OF ARTIFICIAL LIGHTING

The quantitative criterion of lighting of production rooms accepted the minimum illumination of working surfaces which depends on the following factors: degrees of accuracy of the visual work caused by a general characteristic of work and the extent of object of distinction; contrast of object of distinction with a background and characteristic of a background; the applied system of lighting.

Lighting installations have to create not only the demanded illumination, but also to meet the requirements of norms for quality of the lighting created by them it: restriction of the osleplennost created by lighting installation at hit in sight of bright parts of lamps; the reflected brightness – reflection of lamps from working surfaces in the direction of the eyes working; elimination of relative depth of a pulsation of a light stream of light sources, by restriction of coefficient of a pulsation of illumination at production of the light sources applied in lighting installation.

For simplification of rationing, ensuring uniformity of a choice of the normalized parameters at design of lighting installations and control of their state branch norms of artificial lighting in use serve.

SYSTEMS AND TYPES OF LIGHTING

On ways of placement of lamps in production rooms two systems of lighting differ: system of the general lighting and system of the combined lighting.

The system of the general lighting is intended as for lighting of all room in general, and located in workplaces, and surfaces. At the general lighting lamps are installed only in the top zone of the room – directly on a surface of a ceiling or are suspended to it, on farms, on walls, columns or on the production equipment.

For system of the general lighting distinguish two ways of placement of lamps – uniform and localized.

At uniform lighting lamps are installed by ranks with the identical or not strongly distinguishing distances between them. The distance between lamps among is also accepted by the identical. Such lighting is called the general uniform and gets a job in shops with the equipment which is evenly distributed on the area.

In certain production rooms happens it is necessary to create higher illumination for separate sites, by more frequent installation of lamps, reduction of height of subweight of lamps, increase in power of light sources or combined use of different ways. Such lighting is called as system of the general localized lighting and is applied on works sites where the most hard visual works are carried out.

The system of the combined lighting is applied in rooms where delicate and exact visual works are performed, on workplaces where it is necessary to have strictly certain or variable direction of light for improvement of visibility of relief objects of distinction or where a certain spectral structure of light is required.

At the combined lighting the general lighting, with uniform placement of lamps and local lighting by the lamps installed on workplaces in close proximity to a working zone indoors is provided.

LIGHTING MEANS. GENERAL REQUIREMENTS

Lighting means to which light sources and lamps belong, are the most important components of lighting installations. The right choice of types and capacities of light sources, and also types of lamps in production rooms has decisive impact on operational qualities and profitability of lighting installations, on compliance of artificial lighting to requirements imposed to it.

For the light sources used in production buildings, most the following indicators have importance:

Light return, i.e. the radiated light stream on unit of power consumption, lm/W. Light return characterizes power profitability of a light source.

Duration of burning of light sources which is one of the major operational characteristics;

The chromaticity of radiation (spectral structure of light) having crucial importance at a choice of light sources in rooms where the correct color rendition at artificial lighting is required;

Ability of light sources quickly to light up after blackout owing to the food termination;

Value of recession of a light stream during service life (this indicator influences the stock coefficient considered at lighting calculation);

Influence on light and electric characteristics of a light source of level of fluctuations of the feeding tension;

Influence of air temperature in installation sites of light sources and lamps for their work.

At a choice of light sources for production rooms it is necessary to give preference to light sources being energetically economical and possessing long service life, for reduction of initial costs of lighting installations and expenses on their operation during time of operability of lighting installation.

LIGHTING INSTALLATIONS FOR PRODUCTION ROOMS ON THE BASIS OF LED LIGHT SOURCES

At design of lighting installation the preference is given in modern conditions to LED light sources.

The offered type of illuminants has a number of advantages: it is steady against ambient temperatures, vibrations and casual blows, steadily work at the lowered tension.

Differ in instant ignition when giving of the feeding tension, has the built-in protection against power surges and short circuit.

Besides, the LED light sources and lamps manufactured on their basis have excellent quantitative and quality indicators: the high luminous efficiency reaching the size of 130 lm/W that allows to save significantly the electric power during the entire period of existence of lighting installation; possess high characteristics at a color rendition, the index of a color rendition (CRI) exceeds 80-90 (Ra˃80); the coefficient of a pulsation is no more than 3%, and at times at all is absent; have long the service life exceeding 50 000 hours of continuous work.

SPECIFICATION ON LIGHTING CALCULATION. UNITS AND NORMS ACCEPTED AT LIGHTING CALCULATION

At lighting calculation of lighting installation the following data were assumed as a basis:

| Geometry of the room, m

|

120*20*5

|

| Height of subweight of lamps, m

|

5

|

| Illumination on a working surface from system of the general lighting, lx

|

200-300

|

| Stock coefficient for artificial lighting (The settlement coefficient considering decrease in illumination or brightness in use of lighting installation owing to pollution and nonrestorable change of the reflecting and passing properties of optical elements of illuminants)

|

1.5

|

| Uniformity of distribution of illumination

|

more 0.7

|

| The most admissible specific rated capacity of artificial lighting in production rooms, W/sq.m

|

no more 8

|

| General lighting system

|

Lighting, in which lamps are placed in the upper zone of the room uniformly (uniform illumination of the total) or in relation to the location of the equipment (localized general lighting).

|

| Conditional work surface

|

Conditionally accepted horizontal surface located at a height of 0.8 m above the floor.

|

LIGHTING DECISIONS. THE RECEIVED RESULTS

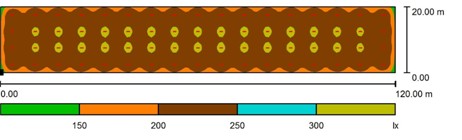

Option 1. Lighting installation on the basis of the universal LED industrial lamp of the LT PROM-100 series.

| Number of lamps LT PROM-100, pcs

|

68

|

| Total power consumption, W

|

6800

|

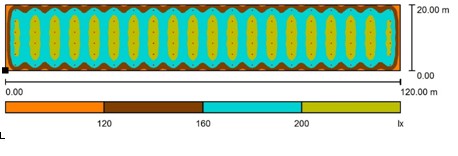

Option 2. Lighting system based on universal LED industrial lamp FL BH-100

| Number of lamps FL BH-100, pcs

|

120

|

| Total power consumption, W

|

14316

|

Conclusion: The lighting system based on industrial lamp FL BH-100 complies with the requirements of normative documents of general lighting of industrial premises.